Brewing industry should unite to reach sustainability goals says Stone & Wood

The age-old argument over the relative merits of bottles versus cans debate needs to be dropped because there is a clear winner, and the industry should work together to come up with solutions to sustainability issues throughout the lifecycle of beer according to James Perrin, sustainability manager at Stone & Wood.

He urged the industry to put the argument to bed at his presentation Bottles vs Cans, Small vs Large…What’s more sustainable? at this year’s BrewCon, at which Stone & Wood also won the Community Initiative of the Year Award for their inGrained Foundation which support grassroots charities at the Indies Awards last night.

“Craft beer is somewhat of a poster child for sustainability,” Perrin said.

However he admitted that this may not be a totally honest conception of the industry.

“Big brewers have more resources and economies of scale,” he said, highlighting the $2 million investment Lion has recently made in solar energy, something many small and even medium brewers might only be able to aspire to, even with their comparably smaller size.

But while independent brewers might not necessarily be able to invest as much in sustainability, there are things they can do to make their processes, right from raw materials through to packaging, waste and landfill, fit the definition better.

“Sustainability is more than just brewing operations, you’ve got to think about the broader supply chain,” he explained.

“We’re starting to see some brewers globally focus on this stuff, but it’s harder to communicate.”

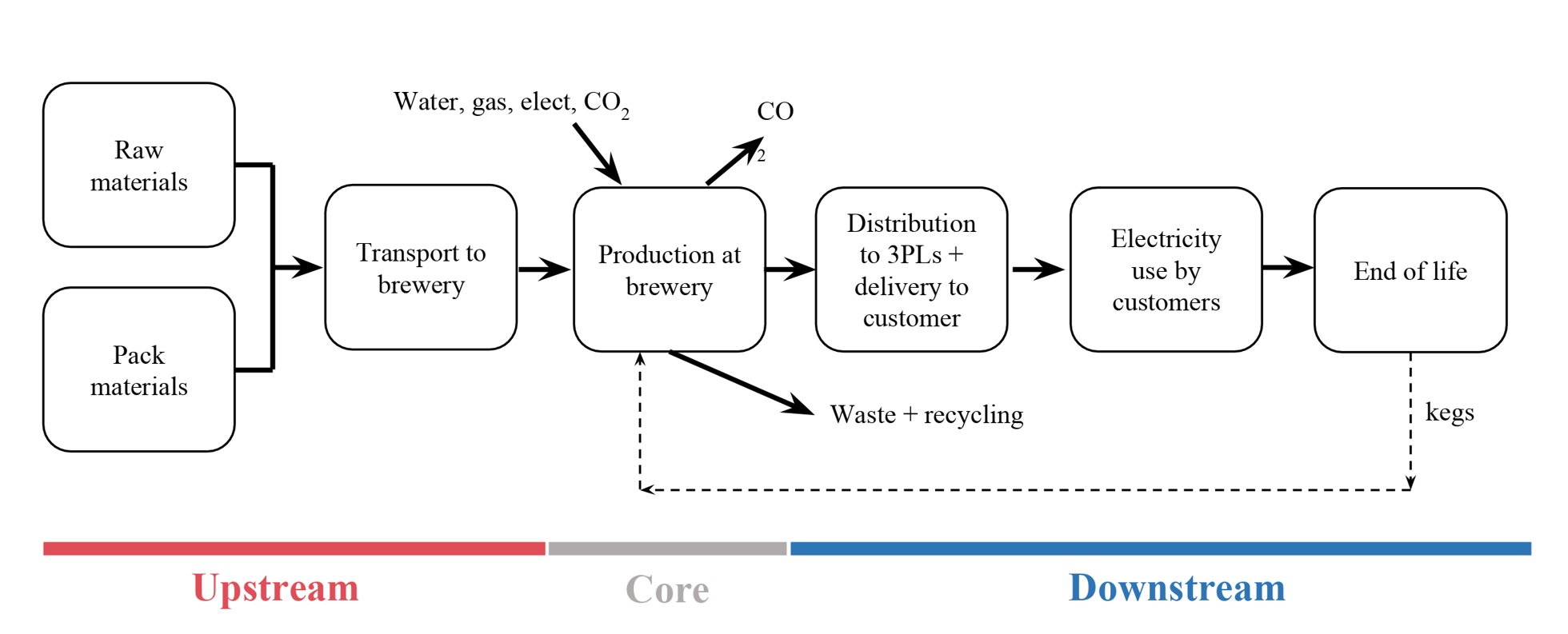

“Lifecycle analysis basically measures the environmental footprint of a product from cradle to grave – from the production of all raw materials for beer and packaging, all the way down to landfill end of life,” he explained.

This focus on the whole supply chain, from “cradle to grave” makes communicating and understanding the extent of sustainability and problem areas more difficult, but there are things brewers can look at, Perrin said.

“We’re not perfect [in this industry] we use a lot of resources, beer is a luxury item. [We need to look at] what our contribution is and focus on how we can improve it.”

Bottles vs cans

Since theadvent of the beer can in 1935, brewers have been fighting over the merits of the can versus the bottle.

Perrin said that Stone & Wood had brought in consultants to look more closely at the complex issues of sustainability and carbon emissions throughout its own supply chain.

“Pack materials are by far the biggest footprint,” he said, explaining why they’d looked into this contentious topic when it came to sustainability analysis.

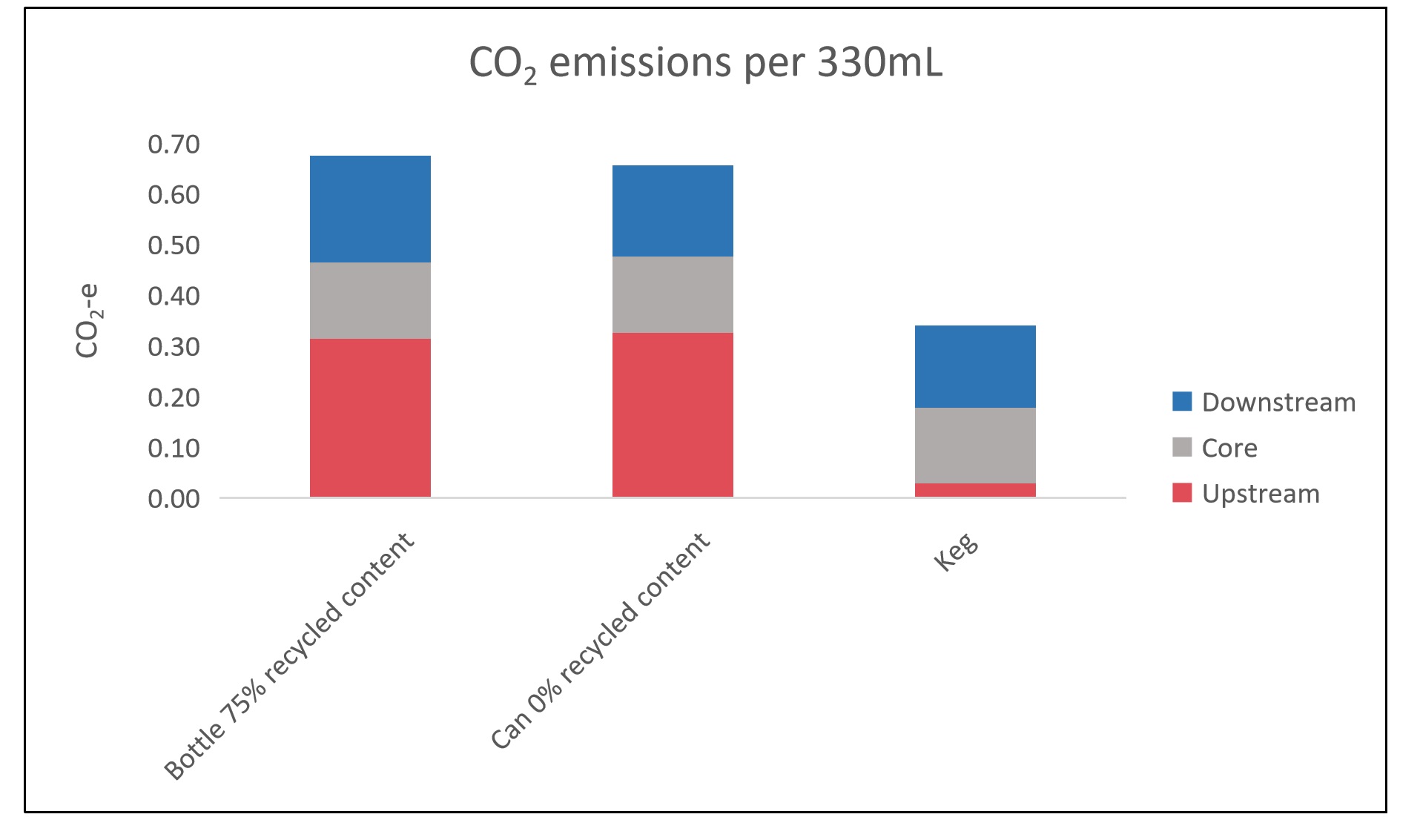

They found that while the grams of CO2 emissions from bottles and cans were largely similar (based on Stone & Wood’s model of 75 per cent recycled glass bottles and virgin aluminium cans which he said are the standard in Australia), cans edged to the front in terms of their sustainability credentials.

However they both still cause much greater emissions than using kegs.

“The biggest impact [on emissions] is the production of the bottle or can. [The argument over them] can be put to bed because cans emit slightly less grams of CO2 than bottles.”

He said Stone & Wood had begun to look at ways to further improve sustainability in its supply chain, sending separated glass directly to recycling facilities so it does not get mixed up with other glasses en route and subsequently sorted again in an attempt to improve sustainability outside direct brewery operations.

“It’s really important to get [your own] backyard brewery operations in order first” he said.

Working together

The next thing to work on is a cohesive, industry-wide attitude to sustainability.

Perrin highlighted industry-wide projects globally like the refillable bottle schemes in the US and the eco-friendly and edible six pack rings made out of malt, barley and wheat, as examples of how national brewing industries are working together to tackle problems which may not be so easy for an individual brewery.

“[It’s about what can we as an industry focus on. We all have supply chain, same customers and distributors, it’s about how can we get together [and look at these issues]”

He called on brewers across the country to join in the conversation on what they can do to develop industry-wide sustainability initiatives, and deal with problems like the recycling of malt bags which is notoriously difficult, or how the industry can look at reusing the CO2 emitted during fermentation processes, instead of buying it in new.

“Sustainability is more than just efficiency in the brewery. It’s more than just your supply chain, it’s about the community.

“We’re an integral part of local communities, we all support and apply that localisation.”

He said many independent beer consumers are paying more because they want to support local, and support sustainability-conscious initiatives.

“So this is a bit of a call to action, I’d like to form some sort of forum and start a conversation with independent brewers on what we can do,” Perrin finished.