How BrewDog brew and bottle

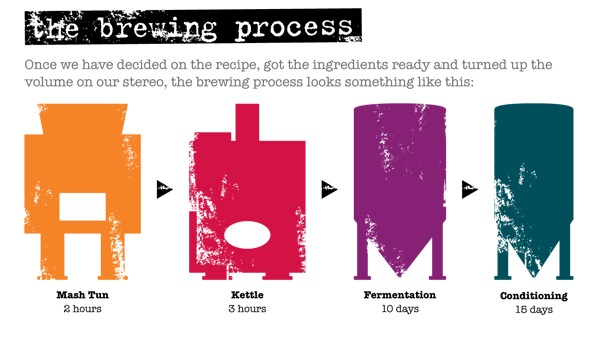

When they’re not freezing their beers to increase the alcohol or brewing their beer at the bottom of the North Sea, Scottish brewers BrewDog brew fairly traditionally.

In their current newsletter, they take a look at their brewing process – partly because of the recent Great British Beer Festival brouhaha. We thought it was a good illustration about the craft brewing process and have reproduced it below, with permission. You can subscribe to the newsletter – Hop Propaganda – here.

How We Bottle

With the recent debate surrounding craft beer and real ale we thought we would give you a behind the scenes look at what actually happens when we bottle our beer.

With cutting edge craft brewers all over the world constantly refining production methods as we strive to improve every aspect of our beers, no longer does a beer need to be either sterile filtered, pasteurized or bottle conditioned. There is a new way of packaging craft beers. One which blurs the old distinctions. Pioneered and perfected in the US craft beer revolution and now practised by leading craft brewers the world over.

So here is an inside look at how it goes down at BrewDog HQ.

After the boiling, our wort is fermented under pressure in closed cylindroconical uni-tanks, so most of the CO2 in the final beer occurs naturally from the initial fermentation. We currently have 30 tanks, ranging in size to the original 20HL ones we started with to our

6 newest 200HL tanks, which are outside because we kinda ran out of space.

After fermentation and during the second week of maturation we hop the hell of out of our beers. Dry Hopping is the process of adding loads of hops to a beer at a low temperature after fermentation. This process is a staple of the US craft brewers but seldom used in Europe.

Because the temperature is low, dry hopping imparts no hop bitterness but instead an avalanche of aroma and flavour. The mesmerising aroma of our Punk IPA, 5am Saint and Hardcore IPA which explodes out of the glass is due to the extensive dry

hopping of these beers.

The bulk of the dry hops settle in the cone of our tanks and we draw out the beer from a special valve above the hops. Here is Stewart with some dry hopped punk from FV 12, check out how hazy the hops make it!

After dry hopping and before filtration we hold the beer at 0° for 7 days. This period ensures stability and shelf life in the bottle without adding nasty preservatives or additives to our beers.

Our beers are often slightly hazy and this is because we filter them so lightly. Sterile filtration (an aggressive filtration practised by most brewers) strips out flavour, aroma and mouthfeel from a beer.

These are things that we work really hard to impart in our beers, the last thing we want to do is remove them before bottling! We prefer taste over absolute clarity. The shelf life in our beer comes from the sheer amount of hops (which also act as a natural preservative) and the cold conditioning time.

After conditioning for 7 days, the still hazy beer goes to our DE filter (in the photo above) for a light filtration to around 5-6 microns, which still leaves some yeast and still leaves all the flavour and mouthfeel in the beer. Sterile filtration (boo!) is to 0.45 microns.

Does this make our beer real ale? Probably, but who really knows anymore. And who actually cares? A new way has emerged with the craft brewing wave that transcends these out-dated conventions.

After the DE filter, the beer goes from a final trap filter (to catch any illusive hop particles), through our handy flow meter (so we know how much beer we have to package) and into one of our bright beer tanks. This light filtration process takes the beer from hazy to pretty clear.

In the bright beer tank (or BBT for short) the lightly filtered beer is checked for CO2 levels and we then adjust this in tank prior to packaging if necessary.

Then the beer either goes to our single head keg filler. Or to our small bottling line for packaging and prepares to be sent out to craft beer drinkers all around the world.

The gentle filtration process we use merely removes the hop bits from dry hopping and the char from the whisky cask aged beers and makes the beers almost bright to the naked eye.

The aromas that come through when you don’t aggresively filter is quite amazing. The intense aromas and flavours that come from our beers is in a large part due to the maturation and packaging process we use and the skill of our Head Brewer Stewart Bowman and his team.

We are selfish and we brew beers that we want to drink, regardless of the cost of the ingredient or how arduous the process is. Which is why we will stick to dry hopping our beers, giving them plenty of maturation time and filtering them as lightly as possible.