Colonial Brewing Co. case study

Content published as an Announcement is produced by the business(es) named in the announcement and remains unedited by Brews News.

Born in Margaret River in 2004, Colonial Brewing Co. makes sure every single brew is made with care, by people who’ve devoted their life to it. They have created a culture of taking pride in their craft and getting the little details right, controlling every variable with the best equipment available, brewing great beer that is made right every time. In 2015, Colonial expanded and opened another facility in Port Melbourne where they started out doing a few hundred cartons a day to now doing several thousand cartons a day on a full production day.

“Through that time, we’ve had to look at automation and different upgrades for reliability as well as production output. When we first started canning here, we were doing approximately 4 – 5,000 cans per hour and it’s a very manual process with manual six packing, manual case packing and manual palletising,” says Ashley Hazell, Head of Brewing at Colonial Brewing Co. “As we’ve grown, we’ve reached the limits of what that can achieve. We’ve had to look at major production upgrades to find an automation solution, to continue keeping up with demand,” Ashley adds.

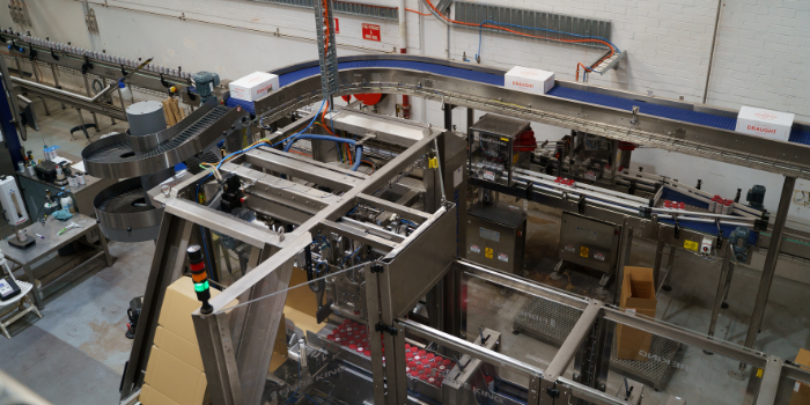

Fibre King’s solution included replacing Colonial’s De-Palletiser with a Fibre King one that unlocked the full capacity of their filling unit, doubling their throughput. Fibre King also supplied a Twin Stream 6 pack and 4 pack Can Carrier applicator, WAP20 Case packer; a wraparound case packer that runs at 14 cases per minute and the CP20 Palletiser. Fibre King also provided the conveyor systems that had to overcome the space constraints and included ceiling hung conveyors and a spiral conveyor.

With their full line running, Colonial is now achieving an average run speed of approximately 10,000 cans per hour with a maximum speed of 14,000 cans an hour. “This is a vast improvement on our previous system which was averaging about 7,000 cans per hour,” Says Ryan Cleghorn, Packaging Leader at Colonial Brewing Co Port of Melbourne. “The equipment has vastly improved our run speed. We’re seeing the ability to keep our oxygen lower in can and by running much faster than we used to be able to get more done every day. It’s unlocked further capacity for us as a brewery as a whole.” Adds Ryan.

“Coming into summer, in the busy period when we’re normally under the pump and struggling, we should be able to comfortably get through safely and efficiently. Overall major quality improvements for us,” Says Ryan.

Colonial has also seen a reduction in their wastage as a result of the new line. Decreasing from 3 to 4% can wastage over a run and volume wastage down to 1% or less. Their carton wastage is also down to approximately 30 to 40 boxes over a 4,000 carton run.

Colonial has been able to increase production and output and reduce direct labour costs. “Our original line needed three to four people to run approximately 4,000 cans per hour average speed, but with our latest upgrades we’re looking at more like 12,000 – to 14,000 cans per hour with two people,” Says Ash. “As we’ve grown, we’ve managed to keep the same people but create a larger output by automating the manual processes and allowing the people to focus more on the technical task of maintaining good beer quality rather than just putting kickbacks in boxes,” He adds.

“We looked at other companies but we chose Fibre King in the end because they were able to fit our needs end to end. Some of the other companies were able to help outsource some equipment but we really wanted one manufacturer to do everything including the install and integration so that it all came together and we only have one point of call if we have issues later down the track. We found Fibre King really good to work with, their technical staff that came out and helped us install it were amazing. We have existing lines to integrate with so we had to run the old line while building the new one and they were more than accommodating helping us to develop our systems and develop our new equipment whilst working around our production schedule and that was probably one of the best things I could have done because we’re an active brewery and we couldn’t just stop to install this new equipment we had to keep it running and they were excellent in helping us achieve that,” Finishes Ash.

Fibre King has worked with countless breweries across Australia providing them with affordable, compact solutions that helps them get their product to market more efficiently and cost effectively. Fibre King is always adding to their craft size range of equipment and are able to work with brewers as they grow to meet production demands. Their canning line solutions can also be altered to suit bottle applications. If you find that you can no longer keep up with manual packaging processes then give Fibre King a call to discuss how they can help automate your production line to unlock your full potential on 1300 831 330.